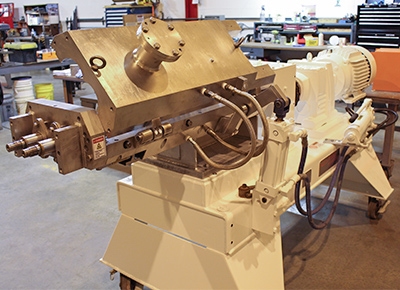

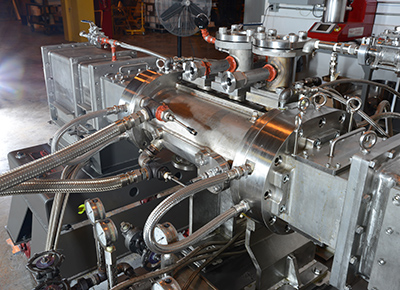

A variety of building products use continuous manufacturing equipment because of the many benefits they offer. Some of the equipment that applications in this industry use include the Continuous Processor (CP), Self-Contained Processor (SCP), and Continuous Hybrid Reactor (CHR). This equipment offers a highly efficient method of mixing doughs and pastes of high viscosity levels. Additionally, continuous manufacturing systems allow for efficient solvent and moisture removal and inert gas blanketing to protect your oxygen sensitive products.

Building Products Key Standards and Other Capabilities

Our equipment ensures that customers in this industry meet certain industry standards, including OSHA and ASME pressure vessel standards. While continuous manufacturing may have high upfront costs, the increased efficiency of this equipment will lead to increased ROI over time.

We offer continuous manufacturing equipment for applications such as:

- Shingles

- Roof coatings

- Carpet backing

- Loaded polyurethane foam

- Joint compound

- Gypsum board

- Caulk

- Plummer’s Putty

- Construction Adhesives

- Synthetic stone and brick

- Reflective marking materials

Advantages

When using continuous mixers and processors from Readco Kurimoto, customers in the building products industry experience numerous benefits. Our systems allow for consistent production, eliminating the risk of variations from batch to batch. They also offer fully automated production, more efficient on-demand production, just-in-time production, and an enclosed design.

Our continuous manufacturing equipment helps reduce maintenance and provides consistent reliability to meet your continuous production needs. We build our equipment to provide long-lasting service and 24/7/365 operation without sacrificing quality for cost. We also perform lab testing to determine a machine’s scale-up capacity and ensure your products can be made with a 100% success rate.

To make installation smooth, our equipment integrates seamlessly with existing processes while eliminating excess storage processes. In turn, you can experience the advantages of our equipment without compromising the integrity of your current upstream and downstream systems.

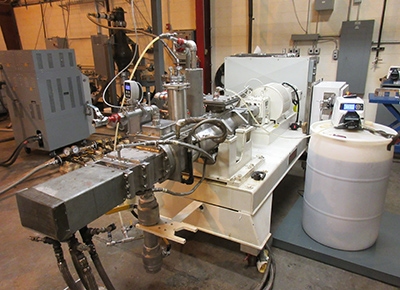

Asphalt Roofing Material Case

One of our customers in the building products industry required a system to meet their individual application requirements. Specifically, this customer needed equipment that would allow for the dispersal and dissolution of fillers and additives into asphalt with fast residence process speeds. They also required dual processors to help reduce or eliminate the need for heating large mix and storage tanks for long periods of time.

Although asphalt benefits from the introduction of certain additives such as oil and rubber pellets, the traditional process for incorporating them is often time-consuming. In addition, the process needs to hold the temperature of the material at over 300° F, which consumes a lot of energy.

Learn more about the products we’ve worked on by downloading our case studies.

Continuous Mixers and More from Readco Kurimoto, LLC

A wide range of applications in the building products industry can see increased efficiency and cost-effectiveness with the use of continuous manufacturing processes. At Readco Kurimoto, we can provide continuous mixers and dry powder blending equipment for customers in industries such as building products, chemical, pharmaceutical, cosmetic, pigment, and food processing.

To learn more about how our equipment can help improve your production capabilities, read our FAQ page.