Industries Served

We strive to be the acknowledged experts in continuous processing and therefore the preferred partner in helping our clients succeed in their industry.

Learn MorePRODUCTS

Continuous Processor

The Readco Continuous Processor is a continuous mixer and reactor used to process food, beverages, pharmaceuticals, cosmetics, and chemicals. We designed them to mix one or more dry materials with one or more liquid materials continuously, producing a homogenous product at the discharge end of the unit. The variable configuration of its co-rotating mixing elements and feed ports allows it to process a wide array of products. It makes the continuous processor ideal for large-scale manufacturing operations where downtime can be costly. The Continuous Processor is customized for specific manufacturing applications with its configurable mixing action, ensuring the thorough mixing of formulations for consistent quality results. The Continuous Processor's optional easy-to-use interface is perfect for busy production environments.

Learn moreSelf-Contained Processor

The Self-Contained Processor is an innovative heat transfer process that uses hollow counter-rotating shafts and a jacketed barrel, each with its independent temperature controls. It creates a continuous, stable, and efficient heat transfer source using heating or cooling mediums. Additionally, the SCP is highly effective at processing materials that transition through difficult phase changes. It allows for a much higher control level over the processing temperature, making it an ideal choice for applications where precise temperatures are critical. The Self-Contained Processor also offers several other advantages, including a compact footprint and the ability to be easily integrated into existing production lines.

Learn moreContinuous Hybrid Reactor

The Continuous Hybrid Reactor is highly effective in applications requiring heat, vacuum, and oxygen-free environments and applicable in producing chemicals, plastics, food, and pharmaceuticals. It uses high temperature and deep vacuum, combined with strategically designed paddles that continuously agitate the material. It exposes the material to more surface area, assisting with reactions, polymerization, and removing monomers, volatiles, moisture, or off-gasses from your product. The Continuous Hybrid Reactor offers many advantages over batch reactors, including increased efficiency and throughput, consistent product quality, and less waste. These reactors process materials sensitive to heat or light, making them an ideal choice for many industrial applications.

Learn moreContainerized Batch Mixer

Our Containerized Batch Mixer is a powder mixer and processing system comprised of a drive station, process module, and high-speed impeller assembly for intimate blending and fine dispersion. This type of system is often used in various industries, including pharmaceutical, cosmetics, chemical, plastics, food, and beverage, for mixing different dry ingredients with up to 15% liquid by weight. The removable high-speed impeller of a Containerized Batch Mixer creates a vortex within the vessel. This allows for the intimate mixing of all ingredients as the impeller tumbles. Additionally, the impeller is integrated into the lid of the processing module, eliminating possible cross-contamination between continuous batches. These features set it apart from other tumble blenders, resulting in a more homogeneous final product with a more refined particle size distribution. Our design enables you to charge, blend, and discharge in one continuous cycle reducing cycle time by 50% or more!

Learn moreAutomate Your Process! Contact Us

ABOUT READCO

Readco Kurimoto, LLC is a global leader in innovative continuous processing solutions, with a complete line of high-performance mixers, reactors, and blenders used in various industries to increase product quality, consistency, and throughput while automating production. Specializing in the design and manufacture of high-performance industrial equipment since 1906, Readco Kurimoto, LLC is dedicated to providing the highest quality, most versatile, and robust industrial equipment available on the market today!

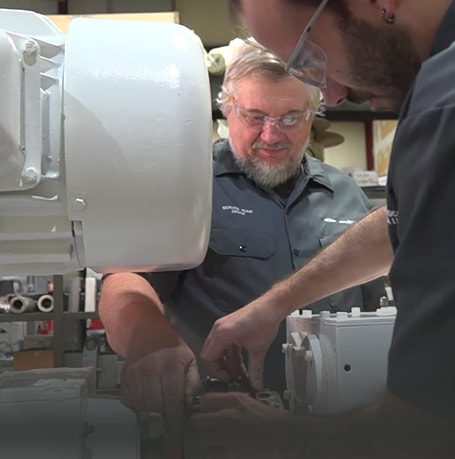

Readco Kurimoto, LLC’s collaborative sales process is designed to create a relationship based on mutual trust and transparency. This begins with a questionnaire followed by in-depth conversations with the prospective customer and our team to understand the required critical success factors. Though a combination of hands-on lab testing in our state-of-the-art pilot plant facilities, education of our technologies, and precise process controls, Team Readco will work to definitively prove we have a machine to overcome your toughest challenges or improve upon your current processes.

Each product line is customizable and specifically engineered to meet the customers' needs, designed to provide the highest performance level and reliability, and backed by a team of experienced professional engineers and technicians. If you are looking to gain a competitive advantage, Readco Kurimoto, LLC is a perfect choice for your most challenging processing needs. Contact Readco Kurimoto, LLC today to learn more about our products and services.

History

History  Mission Statement

Mission Statement  Why Choose Us

Why Choose Us NEWS

Readco to attend Plant Based World Expo in New York, NY. We are showcasing our continuous processer line designed just for food production. We are also unveiling our 2” CP demonstration model with clear barrel. Get a real feel close-up look inside of our equipment and the opportunity to control with our partner Melfi Technologies […]

Read MoreFood Industry Executive has shared a press release for solutions to prevent contamination from exposure to plant environment. Readco’s sealed continuous processors safeguard materials from dust, pests and humidity. Find out more at Food Industry Executive.

Read More